I still remember the first time I tried to replace a ceiling light in my old apartment. I thought it would be as simple as matching colors—black to black, white to white—but one wrong twist and zap, I learned the hard way that not all connectors are created equal.

That’s when I started learning about the different electrical wire connectors types, and honestly, it changed the way I handle every wiring project now.

Whether you’re fixing a lamp, wiring an outlet, or setting up a home workshop, knowing your connector types makes all the difference between a secure job and a short circuit waiting to happen.

What are the main electrical wire connectors types?

You’ll generally find three primary categories of connectors—twist-on, push-in, and crimp—each with its own perks. Your choice depends on the wire gauge, how permanent the connection should be, and whether you want something reusable.

Twist-on connectors (also called wire nuts) are classics for household wiring. Push-in connectors are newer, faster, and tool-free. And crimp connectors—the tough guys—are your go-to for vibration-heavy environments like vehicles and boats.

Here’s a quick snapshot:

| Type | Best For | Pros | Cons |

| Twist-on | Home wiring | Simple, affordable | Can loosen over time |

| Push-in | Lighting, quick fixes | Fast, reusable | Not ideal for all stranded wires |

| Crimp | Automotive, marine | Permanent, vibration-resistant | Requires crimp tool |

How do twist-on electrical wire connectors work?

I have a soft spot for twist-ons—probably because they were my first wiring win. You strip the wires, twist them together, then screw on the connector until it grips tight. Inside, there’s a coiled metal insert that secures the wires firmly.

They’re commonly found in junction boxes and general household connections. The DIANZHU 180 PCS Insulating Insert Twist Electrical Wire Connector is a great example—it’s color-coded for different wire sizes, which keeps things simple when you’re juggling multiple wires.

They come in three main styles:

- Standard twist-on connectors: The everyday option for most residential projects.

- Winged twist-on connectors: Easier to twist and hold, especially when you’re working overhead.

- Waterproof twist-on connectors: Filled with sealant for outdoor or damp environments.

While they’re budget-friendly and easy to use, they can loosen due to vibration—so for permanent or high-vibration setups, I usually pick another option.

What should you know about push-in electrical wire connectors?

When I discovered push-in connectors, it felt like upgrading from a flip phone to a smartphone. No twisting, no crimping—just strip the wire and push it in. These connectors use an internal spring mechanism that clamps onto the wire securely.

They’re perfect for lighting circuits and quick installations. The ROBOWAY CH2 Premium Spring Wire Connector and Serplex 10Pcs Lever-Nut Wire Connectors are solid choices if you want reliability and flexibility.

I especially love lever-nut connectors (like the WAGO 221-412). You flip the little lever up, insert the wire, and snap it down—done! They’re compatible with solid, stranded, and fine-stranded wires, making them a universal favorite.

The only downside? They’re a bit bulkier than twist-ons, so space can be tight in smaller boxes.

Why are crimp electrical wire connectors popular among pros?

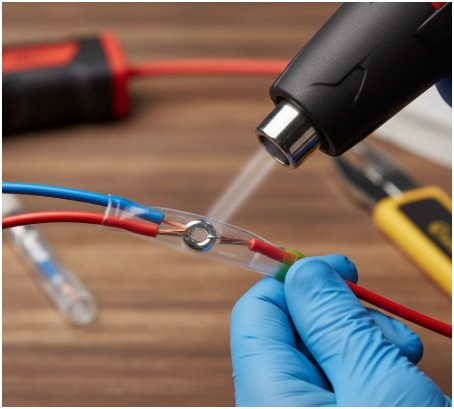

If twist-ons are the beginners and push-ins are the innovators, crimp connectors are the pros. These require a crimping tool that compresses the connector’s metal barrel around the wire, forming a strong, permanent bond.

They’re incredibly secure and vibration-resistant, which is why they’re used in automotive, marine, and aerospace applications. My go-to is the HASTHIP 280Pcs Wire Connector Set, which includes butt connectors, ring terminals, and fork terminals.

Here’s what they offer:

- Butt connectors: Join two wires end-to-end permanently.

- Ring and fork terminals: Connect wires to screws or studs—great for control panels.

- Bullet connectors: Allow easy connection and disconnection without tools.

Some advanced kits even include heat-shrink connectors, which shrink when heated to form a waterproof seal. They’re ideal for outdoor or marine setups.

Are there other electrical wire connectors types worth knowing?

Absolutely—and some of them make your wiring life so much easier.

Terminal Blocks

Think of these as wire organizers. They’re used in industrial panels where you need to connect several wires neatly. The PCT-215 Terminal Block Splice is a modern version with levers instead of screws, which I find much easier to use.

Solder Seal Connectors

These are hybrid connectors with heat-shrink tubing and solder inside. When you apply heat, the solder melts, and the tubing shrinks, creating a waterproof, permanent joint—perfect for marine or outdoor work.

Insulation Displacement Connectors (IDCs)

If you’ve ever hated stripping wire insulation, IDCs are your best friend. They pierce the insulation and make the connection instantly. I’ve used them for small electronic projects where speed mattered more than looks.

How do you choose the right electrical wire connectors types for your project?

Here’s my quick rule of thumb:

- For home repairs or light fixtures, go with twist-on or lever-nut connectors.

- For industrial setups or cars, crimp connectors win hands down.

- For outdoor or marine projects, heat-shrink or waterproof connectors are unbeatable.

- For control panels, terminal blocks make wiring look like art.

And don’t forget wire gauge compatibility. If the connector doesn’t match your wire size, even the best one won’t hold.

FAQs about electrical wire connectors types

1. Are push-in wire connectors safe for long-term use?

Yes—if you choose high-quality brands like WAGO or Serplex. They’re designed to maintain spring tension over time, keeping the connection secure. However, cheap knockoffs may loosen, so stick with trusted names.

2. Can I reuse twist-on connectors?

You can, but I usually don’t. Over time, the internal coil can lose its grip. If you remove one, it’s safer to replace it with a new connector instead of risking a loose connection.

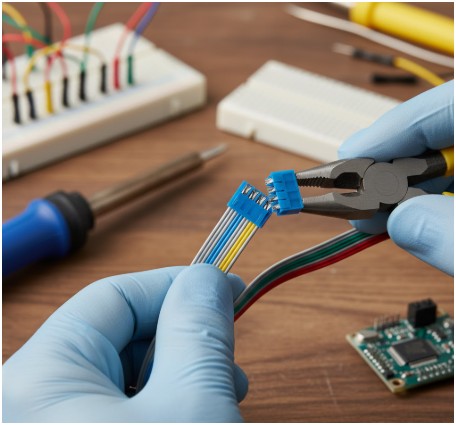

3. Do crimp connectors need special tools?

Definitely. A proper crimping tool ensures uniform pressure and a strong bond. Using pliers instead might seem convenient, but it weakens the connection and can cause failure.

4. Which connectors are best for outdoor wiring?

Waterproof twist-on or heat-shrink connectors are ideal. They protect against moisture, corrosion, and temperature changes, making them perfect for garden lights or outdoor outlets.

Wrapping It Up with a Spark (and a Smile)

If there’s one thing I’ve learned after years of tinkering with wires, it’s this: a good connection isn’t just about electricity—it’s about reliability. Choosing the right electrical wire connectors types makes your work safer, cleaner, and more professional.

My personal tip? Always keep a small kit of different connector types on hand. You never know when a quick fix will turn into a full project. And trust me, when that happens, having the right connector ready can save your day—and maybe even your light fixture.